Oxygen and acetylene regulator pressure settings play a pivotal role in welding, determining the efficiency and safety of the process. Understanding these settings is crucial for achieving optimal results and minimizing potential hazards.

This comprehensive guide will delve into the intricacies of oxygen and acetylene regulator pressure settings, providing insights into their purpose, adjustment techniques, and the consequences of incorrect settings. Additionally, it will highlight essential safety considerations and maintenance practices for safe and effective welding operations.

Oxygen and Acetylene Regulator Pressure Settings

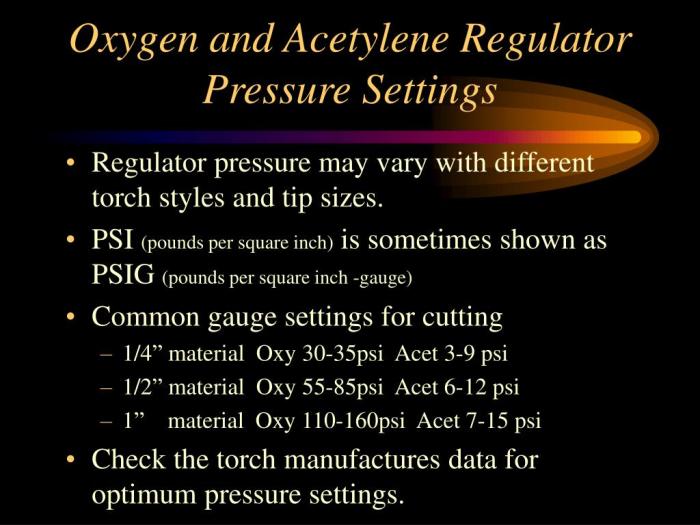

Regulators are essential components in welding, controlling the flow of oxygen and acetylene gases. Understanding the purpose of regulators and the factors influencing appropriate pressure settings is crucial for safe and efficient welding.

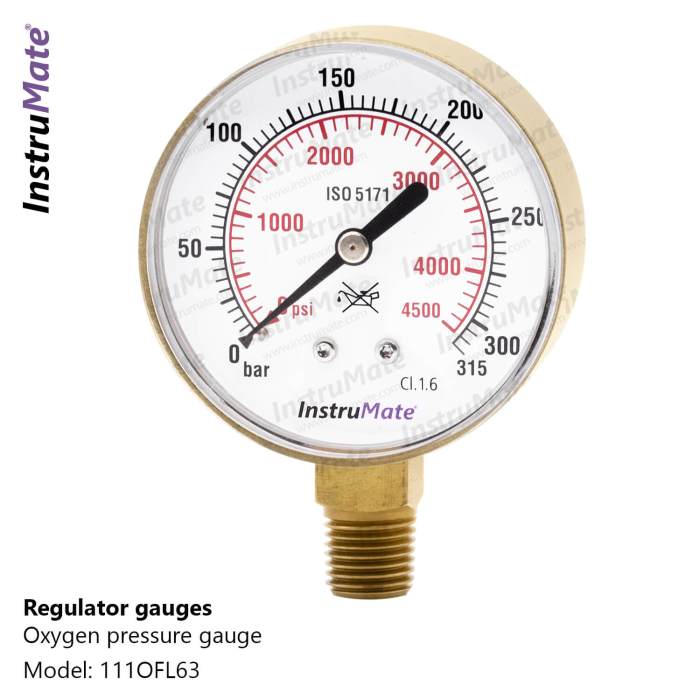

Oxygen Regulator Pressure Settings

- Typical pressure range: 25-50 psi

- Adjustment: Use the adjusting screw on the regulator to set the desired pressure.

- Optimal pressure: Maintain a consistent pressure to ensure proper gas flow and combustion.

Acetylene Regulator Pressure Settings, Oxygen and acetylene regulator pressure settings

- Typical pressure range: 10-15 psi

- Adjustment: Adjust the regulator pressure using the adjusting screw.

- Optimal pressure: Ensure the pressure is stable to prevent backfiring or incomplete combustion.

Effects of Incorrect Pressure Settings

- Incorrect Oxygen Pressure:Can lead to insufficient oxygen supply, poor combustion, and weak welds.

- Incorrect Acetylene Pressure:Can cause excessive acetylene flow, carbonization, and flashbacks.

- Identifying Incorrect Pressure Settings:Monitor the welding flame; an unstable or irregular flame indicates incorrect pressure.

Safety Considerations

- Always follow safety precautions when adjusting regulator pressure settings.

- Regularly inspect and maintain regulators to ensure proper function.

- Store and handle oxygen and acetylene cylinders safely, adhering to manufacturer guidelines.

FAQ Guide: Oxygen And Acetylene Regulator Pressure Settings

What is the purpose of a regulator in welding?

A regulator is a device that controls the flow and pressure of gases used in welding, ensuring a consistent and safe supply to the welding torch.

How do I adjust the oxygen regulator pressure?

To adjust the oxygen regulator pressure, turn the adjusting screw clockwise to increase pressure or counterclockwise to decrease pressure. Refer to the manufacturer’s specifications for the optimal pressure range.

What are the consequences of using incorrect oxygen pressure settings?

Incorrect oxygen pressure settings can lead to poor weld quality, excessive oxidation, or even explosions. It is crucial to maintain the correct pressure for the specific welding process and materials being used.